How Do Aerial Mosquito Control Applications Work?

Mosquito control by air can be effective for communities that need to quickly and efficiently reduce mosquito populations over a wide area to improve the comfort of life or help break vector-borne disease transmission. Aerial applications immediately conjure up images of a bi-wing crop-dusting plane, flying low and dousing the ground directly beneath the plane with a liquid product. That is NOT what aerial mosquito control looks like.

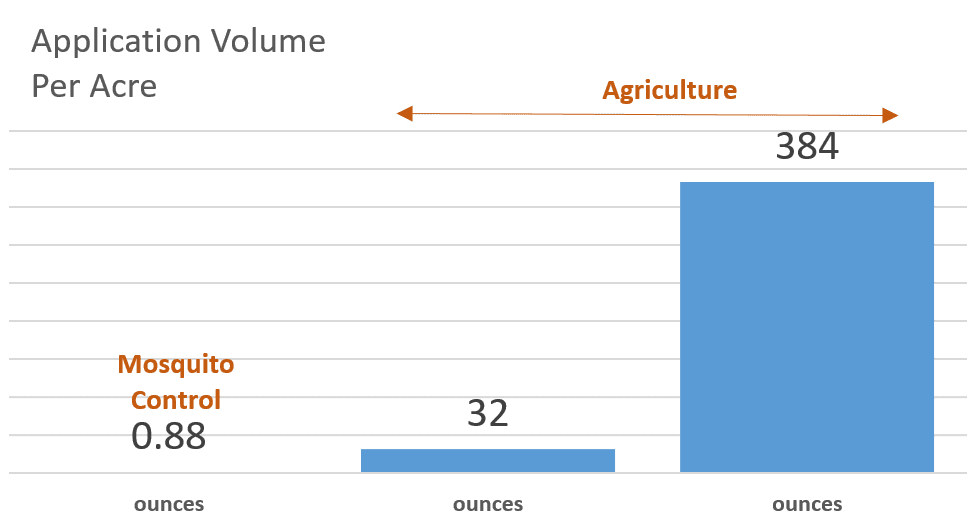

Aerial mosquito control applications use less than an ounce of product per acre. Compare that to the 1 pint to 3 gallons per acre of typical agricultural insecticide applications. (SOURCE: Page 5, EPA Commercial Aerial Application Guide)

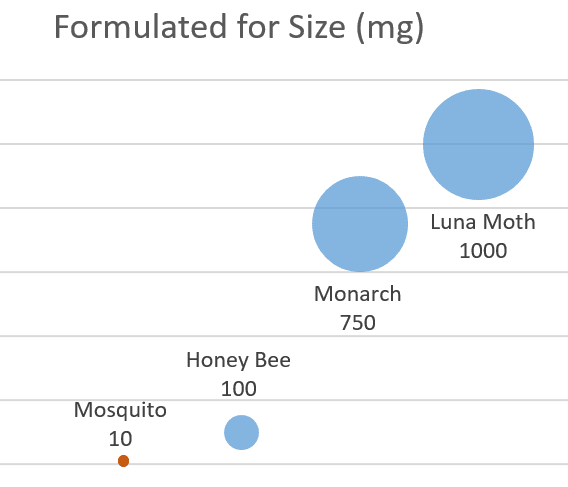

Mosquito control products are formulated specifically for a mosquito’s body type and size, which on average weighs between 2.5 to 10 mg. These are products that are designed to make physical contact with adult mosquitoes in-flight. When a product lands on the mosquito’s body, it starts to work by attacking its nervous system.

For comparison sake, honeybees weigh about 100 mg, Monarch butterflies and Luna moths are 750 to 1000 mg in body weight.

Adult mosquito control products are designed to be delivered through ultra-low volume (ULV) nozzle systems. ULV applications create a fine spray cloud (mist) that is comprised of tiny droplets – think 15 droplets on the head of a pin. These droplets move through the air in order to make contact with in-flight adult mosquitoes.

Because adult mosquito control products work by making direct contact with mosquitoes in-flight, they are done after sunset when mosquito populations are most active. An added benefit to nighttime applications is that most other beneficial insects, like bees, caterpillars and butterflies, are sheltered in their hives during that time.

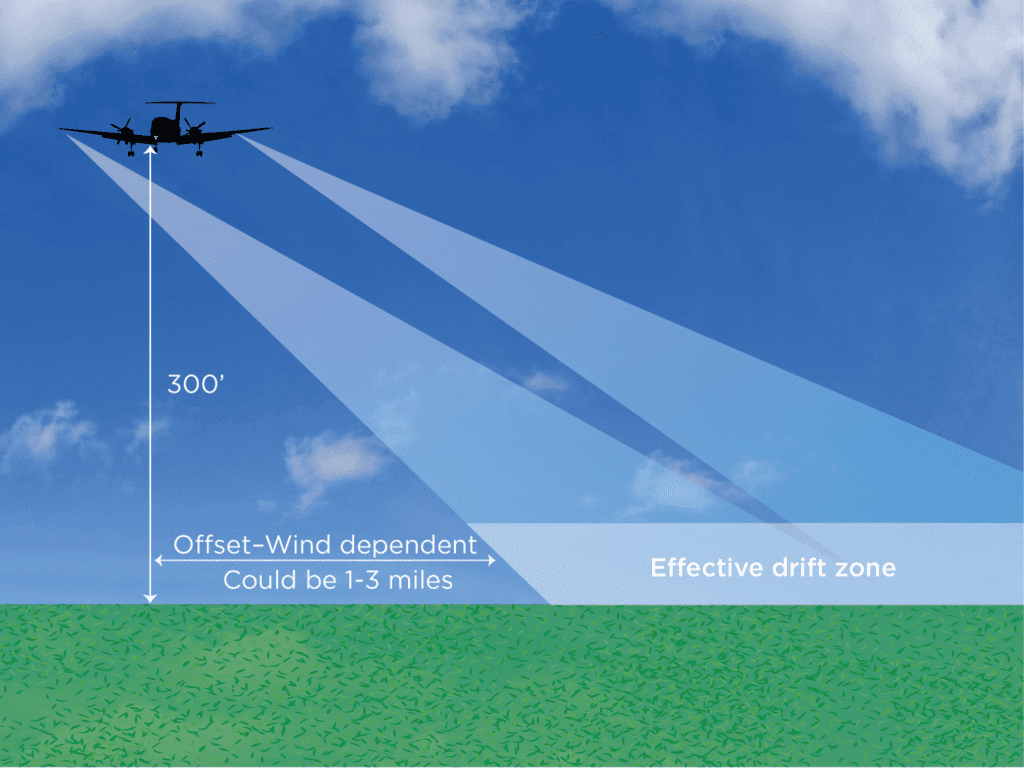

The planes used for aerial mosquito control applications are quiet, twin-engine jets that fly at 300 feet and 175 mph during application. They are flown by experienced pilots with specialized training in mosquito control applications. And because the treatments are done at night and at low altitudes, pilots wear military-grade night vision goggles for safety.

Mosquito control products are designed to drift through the air and make contact with adult mosquitoes in flight. Weather plays a big factor in how a spray cloud behaves. As such, mosquito control application aircraft are equipped with sophisticated onboard navigation software that takes into account wind speed, wind direction, humidity and temperature in real-time and constantly adjusts a plane’s flight path. This software works in tandem with the aircraft’s spray system to automatically turn the spray nozzles on and off according to the treatment zone map and exclusion requirements.

One of the most important things to understand about aerial mosquito control is that the aircraft always flies an offset flight path. Mosquito control products do not drop straight to the ground when they leave the aircraft’s nozzle system. Weather conditions influence how the droplets will move through the air. So it’s very common for an aircraft to be flying a path that’s 1-3 miles away from the treatment zone to ensure the product will reach the intended treatment area with precision.