Clarke Operations: The Impact of PCR Lab Capabilities on Control and Application Decisions

While mosquito-borne diseases threaten human health worldwide, implementing an integrated mosquito management (IMM) system can go a long way toward mitigating those risks. Within the IMM network, the surveillance lever acts explicitly as a predecessor to larval or adult control measures and includes practices such as:

– Finding and monitoring known mosquito larvae breeding grounds

– Monitoring birds, equine, and other incubators for mortality and virus exposure

– And most importantly, tracking mosquito populations and testing them for viruses

These activities help professionals determine if, when, where, and how much of their other IMM functions are needed to manage mosquito populations – to act before viruses spread to human populations.

Clarke’s operational division, based out of Roselle, Illinois, is a leading provider of mosquito control services across the United States. To help increase their efficiency and ability to monitor their service area’s mosquito populations effectively – and thus better protect their health – their operations team opted to introduce PCR lab testing of collected mosquitoes to shorten and make more accurate the virus testing portion of the surveillance process.

In this article, Regional Surveillance Manager, Lauren Lavezzi, will discuss Clarke’s PCR lab capabilities and their impact on control and application decisions.

Clarke’s operation division has performed mosquito testing for viruses for several years as part of their IMM strategy. However, up until 2020, they utilized traditional testing methods comprised of RAMP testing of surveyed samples for initial results. These were then sent to a third-party lab for final confirmation via PCR testing. All in all, this process could take up to two weeks for final, confirmed results – a long time for delays in notifications or control when there was potential for hazardous viruses in the community.

Clarke determined to forgo the initial RAMP testing and bring the PCR testing in-house to improve and make this process more efficient. Doing so allowed them to have complete control over their testing process and to receive results more quickly.

PCR testing is a highly sensitive method of detecting the genetic material of a pathogen, in this case, mosquito-borne viruses. The PCR process involves extracting genetic material from a sample, such as a mosquito pool or blood sample, and amplifying it to detectable levels. The amplified material is then analyzed to determine the presence or absence of the target pathogen.

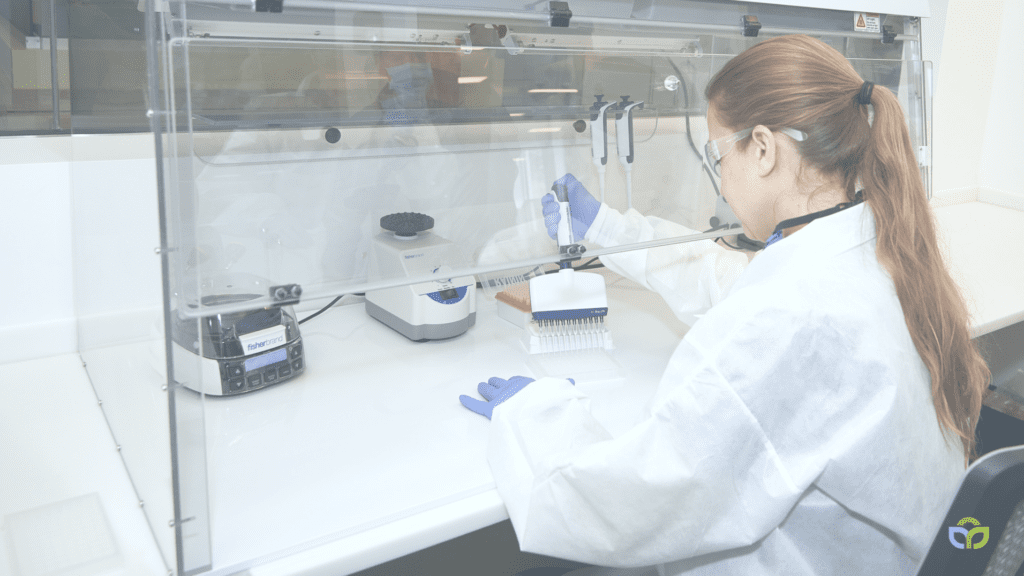

Implementing a PCR lab that was completely operational within Clarke’s facilities necessitated purchasing a range of equipment, including:

– A 24-capacity bead mill for grinding samples

– A Kingfisher Flex for washing samples

– A Qstudio 5 for running PCR plates

– Standard equipment such as pipettes, vortexes, centrifuges, and PCR workstations, duplicated for prep areas to prevent contamination

With the use of this equipment and the heightened capabilities they provided, Clarke’s in-house lab could run up to 90 96-well plates. This was well within the team’s high throughput target.

After the team had purchased the needed equipment in early 2020, the COVID-19 pandemic disrupted Clarke’s in-person training plans before the launch of the in-house PCR lab. Luckily, the surveillance team quickly pivoted, adapting to a successful one-on-one virtual training process that allowed them to set up a safe and efficient PCR lab.

Still, as the pandemic and its effects continued into the following year, supply chain delays and staffing hurdles posed challenges for Clarke Operations during the 2021 season. However, the organization was able to mitigate these challenges by running full plates, minimizing extraneous supply usage, conducting regular inventories, ordering supplies ahead of time and prioritizing staffing responsibilities.

Clarke’s surveillance team currently traps and tests around 3000 samples from five states each season. Depending on demand, they run 90 to 360 tests per week and can have results within 24 to 48 hours of receiving samples. The lab can run up to four plates per week, with each plate taking 4 to 6 hours to complete depending on the individual performing the pipette work.

The in-house PCR lab capabilities have allowed Clarke’s operations and surveillance team to have complete control over their testing process, vastly improving the efficiency and accuracy of their mosquito surveillance program. In addition, with faster turnaround times for results, Clarke’s operations teams can notify communities and internal staff of virus presence more quickly and confidently, setting off other IMM control functions as may be needed. This timeliness is critical during a mosquito-borne virus outbreak, where early information can help prevent the spread of the virus.

Ultimately, investments such as these lead to more effective mosquito control efforts and overall improved public health.

Have any questions about our operational and surveillance teams’ practices? Give us a line – we would love to chat!