Updates and Improvements to Field Cage Trials

Field trials are a valuable tool used to verify product efficacy on susceptible mosquito species and to monitor for the development of resistance within wild mosquito populations – important components of both new product development and evaluating a product’s fit within a mosquito control program.

Overall, field trials are used by both industry and mosquito control programs for:

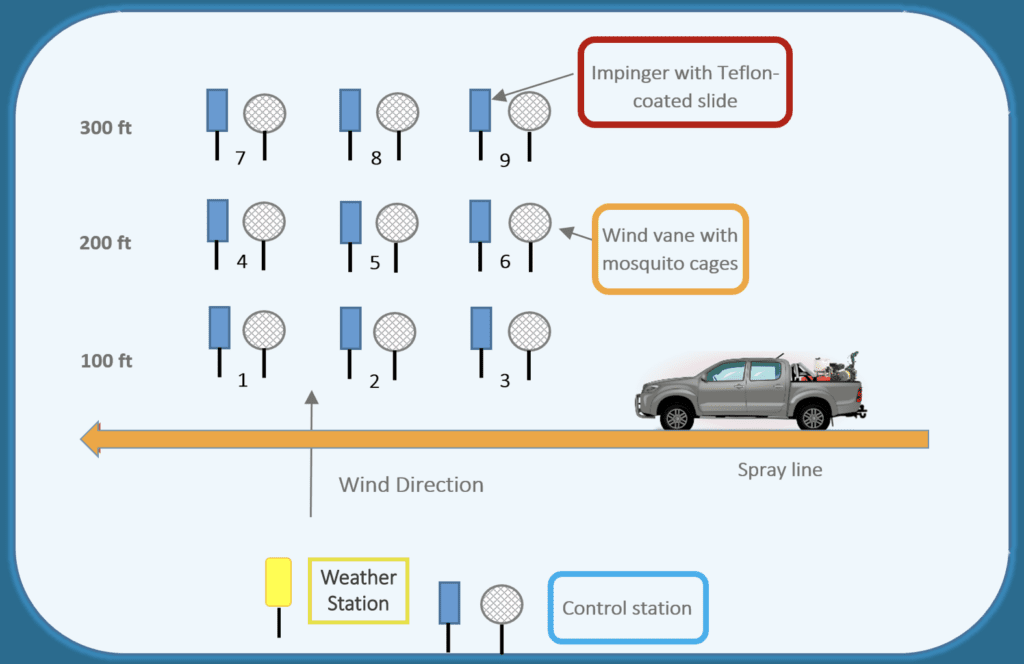

The general setup of a ground field trial involves establishing a spray line that is positioned perpendicular to the wind, along which your ULV spray equipment will travel to apply product. Bioassay cages and droplet samplers are placed downwind from the spray line throughout an open field out to 300 feet – the calibrated spray swath of a ULV sprayer. An additional droplet sampler and bioassay cages are positioned upwind of the spray to serve as controls and to monitor for background contamination.

While this setup may be standardized, the equipment used in these evaluations – as well as the process for consideration of weather is not. The quality and design of equipment must be considered by evaluators, as different designs of bioassay cage and the methods of positioning those cages in the field can all influence the results obtained. Additionally, the consideration of weather in field setup is an important facet of field trials, and failure to be responsive to wind conditions can greatly impact efficacy.

Initially, Clarke’s team used PVC and rebar to arrange a field setup, which had to be hammered into the ground but picked up and reset whenever the wind changed direction – but also limited the sites that could be used for testing.

After visiting the Sacramento-Yolo Mosquito and Vector Control District, the team began using tripods. These tripods were easily usable on various surfaces, such as the hard compacted dirt of the desert, paved surfaces, or soft soil. This switch also reduced setup time, allowed the team to be more responsive to changing weather conditions and was safer than the previously used rebar, which often had to be hammered into the ground well after sunset.

To utilize the tripods with wind vanes, Clarke’s field science team ventured into 3D printing to create adapters and appendages customized to the tripods, making uniform equipment produced at a low cost per unit.

Traditionally, weathervanes are placed on the field cages to secure mosquito cages and ensure their orientation towards the product spray cloud.

The original vane design required heavy maintenance and became unstable over repeated use. It was also bulky and had too many parts – Clarke’s original design utilized over 25 components, which made for costly, individualized production.

The team developed a new style of weathervane that addressed these concerns by reducing the number of parts to 14 in total. Five of these parts are easily made in-house using a 3D printer, and a skateboard bearing was adapted for more accessible, cheaper sourcing. This bearing was also more responsive to more minor wind changes.

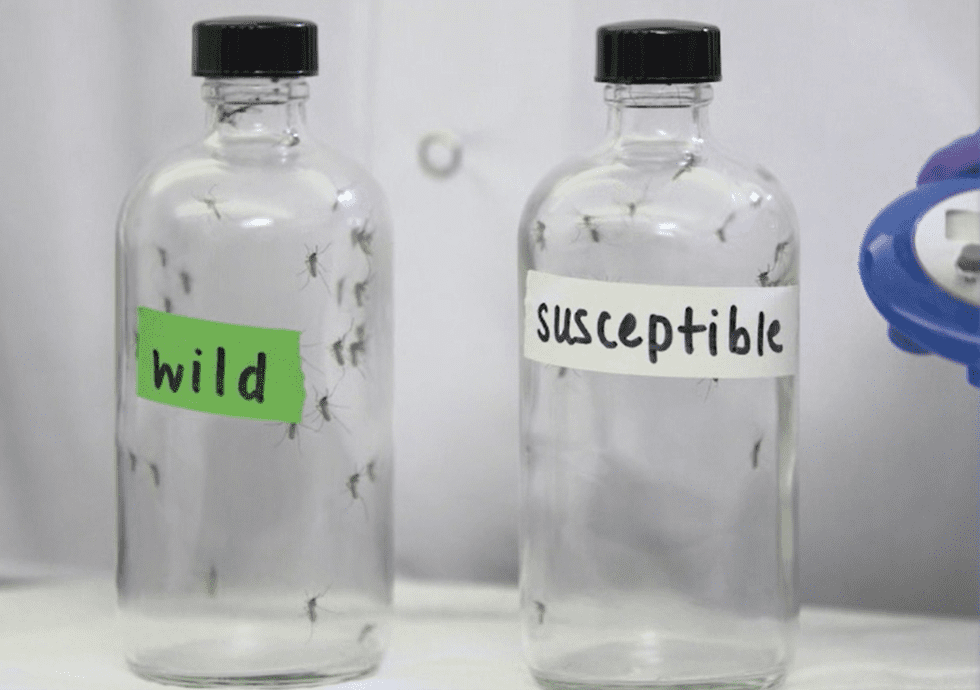

The most significant benefit realized was the ability to customize the vane with five magnet points allowing for five bioassay cages to be attached at one time. This development allowed for five mosquito populations to be trialed concurrently, greatly increasing the efficiency of trials while giving a more direct evaluation of products across test populations. Previous designs only permitted three mosquito species testing at a given time.

In all, the improved weathervane design allowed for the following:

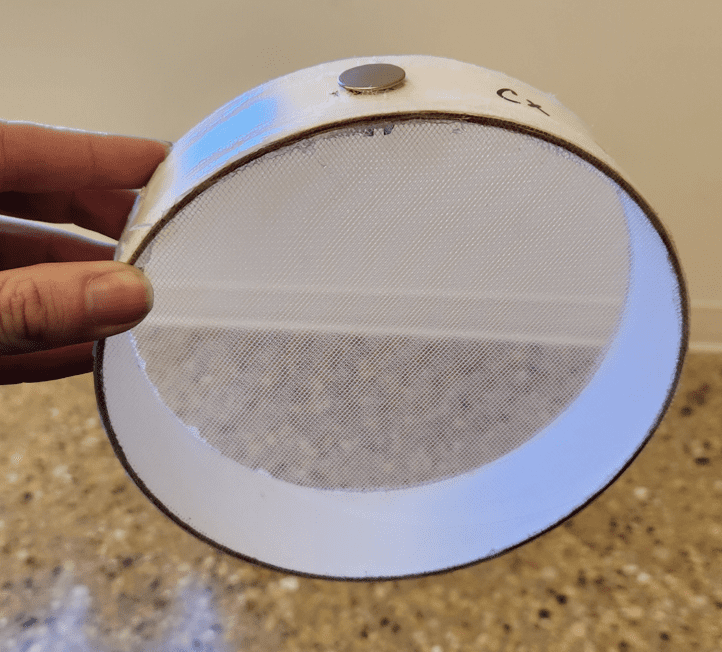

Bioassay cages used in field trials vary widely and are typically handmade or reusable metal cages. Clarke’s field science team utilizes a flat-faced cylindrical cage design. In a study by Bradley Fritz and others, this cage had the lowest reduction in product spray penetration at various wind speeds.

Clarke’s original cage design was handmade with tulle stretched over a cardboard ring using an embroidery hoop. This tulle was then hot glued to seal it in place. Unfortunately, after this timely construction process, the team still faced unwieldy issues with placing mosquitoes in the cages and setting them up in the field space.

Mosquitoes were inserted via a hole in the bottom of the cardboard ring, which then had to be plugged with metal grommets. Between uses, these grommets needed to be removed and cleaned thoroughly – an inconvenient and timely process that hindered the team’s efficiency.

To counter this, the team worked with a manufacturer to begin machine-making bioassay cages, which resulted in overall cost and time savings when factoring in the labor costs of constructing thousands of cages.

This new design features a movable middle ring that slides to allow access into the cage, allowing the team to aspirate the mosquitoes straight into the cage and remove any dead mosquitoes before a test spray is conducted.

This center ring also features a metal attachment for the weathervanes, removing the need for a metal grommet.

Clarke’s field science team continues exploring other opportunities to improve the field trial process, such as reusing spray cages and evaluating whether or not it is necessary to transfer mosquitoes that have been sprayed out of bioassay cages into holding cages.

In addition, the team is trialing new technologies, such as new weather monitoring stations.

Improvements to the equipment and methods used in caged mosquito field trials are crucial for obtaining accurate and reliable product efficacy and resistance results as new products emerge.

Clarke encourages districts and mosquito control programs to trial these improvements for themselves – after all, more consistent field testing means more consistent and comparable results. Our goal is to make these designs available for public use – as we believe there should be no gatekeeping of new technology when it comes to public health.

Interested in obtaining any of the designs discussed above? Reach out to our team below – we’re happy to help.