Navigating the EPA Registration Process for Mosquito Control Products: A Comprehensive Guide

Beyond posing a nuisance to humans, mosquitoes also pose a significant threat to public health, vectoring severe diseases including West Nile Virus (WNV), Zika and more. Effectively managing their populations requires the responsible, effective use of specialized mosquito control products.

Before these products hit the market, they must undergo a rigorous registration process mandated by the Environmental Protection Agency (EPA) to ensure they do not pose unreasonable risks to people, pets, or the environment.

This guide will walk through this rigorous process undertaken by mosquito pesticide product manufacturers to get their mosquito control solutions to those who need them most, including:

The Environmental Protection Agency (EPA) is the body responsible for the protection of human health and the environment in the United States.

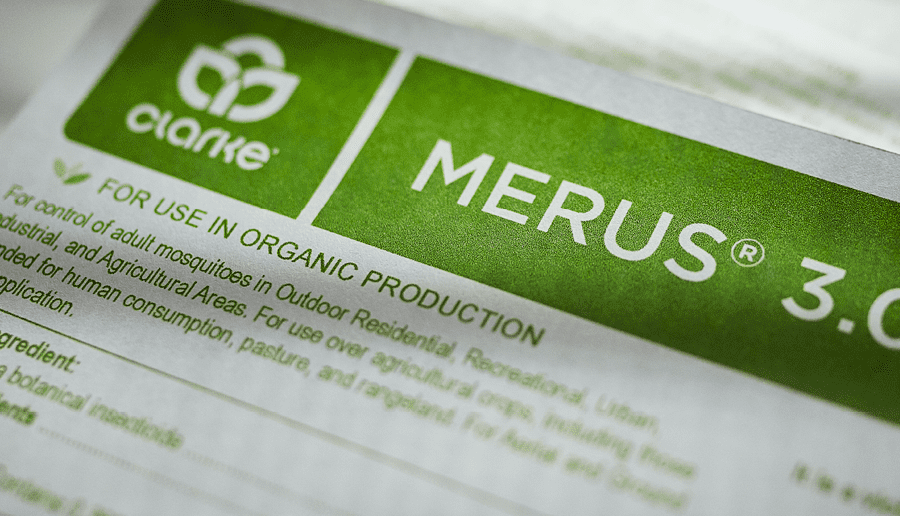

One of its critical functions is regulating pesticides, including those used in mosquito control. This oversight warrants that products intended to safeguard us from disease-carrying mosquitoes are both effective and safe for the environment and humans. When used according to the label instructions, these EPA-approved products have been determined by the EPA to not pose unreasonable risk to people, pets or the environment.

In order for any mosquito product to be EPA-approved, it must first undergo a rigorous process, including lengthy data collection and field trials on its effectiveness and safe usage, detailed descriptions of its composition, active ingredients (AI) and inert ingredients, documentation and label submission, and, finally, comprehensive review of all these materials from the EPA with a final decision on registration depending on their findings.

Before delving into the intricacies of the EPA pesticide registration process, it’s important to understand the types of insecticide products developed by the industry and their use within mosquito control.

Mosquito control necessitates a multifaceted approach, and various products cater to different stages of the mosquito life cycle. These include:

In order to receive EPA approval, each of these products undergo the same stringent registration process. Today, we’ll focus only on adulticides and larvicides.

Preliminary Research and Literature Review:

This begins with a comprehensive literature review of existing research on active ingredients, formulation, and efficacy of mosquito control products. Understanding the current state of knowledge in the field helps design effective experiments and studies.

Data Collection:

Before seeking EPA registration, comprehensive scientific data is paramount. Field trials and lab studies conducted by the manufacturer, as well as independent labs, provide the empirical evidence necessary to support the registration application.

Field trials are conducted to assess the product’s performance in real-world conditions. Field trials are a valuable tool used to verify product efficacy on susceptible mosquito species and to monitor for the development of resistance within wild mosquito populations – important components of both new product development and evaluating a product’s fit within a mosquito control program. Data collected includes mosquito mortality rates, reduction in breeding sites, and overall efficacy.

You can learn more about the set-up, functions, and outputs of field trials here.

Assessing the environmental impact of the product is crucial. This includes studying potential effects on and persistence within non-target species, water quality, and overall ecosystem health. The data collected should demonstrate that the product poses minimal risk to the environment.

Learn more about the effects of mosquito control on non-targets, especially beneficial pollinators, and the steps applicators take to mitigate any adverse ones here.

Safety studies focus on the potential harm the actives within the product may pose to humans, pets, and non-target organisms. This includes toxicology studies to establish if these can cause adverse effects when used as directed. Data from these studies is crucial in establishing safe usage guidelines, as well as from a plethora of other studies conducted by other researchers, labs, companies and, manufacturers.

Efficacy data is the heart of the registration process as it demonstrates the product’s ability to control mosquitoes effectively. This data includes metrics such as knockdown rates for adulticides, larval mortality rates for larvicides, and repellency rates for repellents. Some products may require long-term studies to assess their effectiveness over extended periods. This is particularly important for products designed for sustained mosquito control, such as multi-brood, residual larvicides.

After data collection, thorough analysis and interpretation are crucial. Statistical methods are employed to confirm the validity of the results. The analysis should demonstrate that the product consistently achieves its intended outcomes.

Proper documentation of all data collected includes detailed records of experiments, methodologies, results, and any unexpected findings. This documentation will be submitted as part of the registration application.

By diligently collecting and analyzing this data, manufacturers lay the groundwork for a successful EPA registration application. It provides the scientific evidence needed to demonstrate the product’s efficacy and safety, ultimately ensuring that it meets the EPA’s rigorous standards for mosquito control. In sum, this process can take anywhere from three to ten years to complete successfully.

The actual formulation of a mosquito control product including not only the active ingredients – the ingredients that cause the intended effect – but also any inert ingredients – ingredients essential for the functionality of the formulation, as well as their compatibility, stability must be assessed as part of the EPA registration process.

To explain further:

Active ingredients are the substances responsible for the primary mode of action that controls mosquitoes. As outlined above, they must meet strict criteria for efficacy, safety, and environmental impact, with thorough assessments of their chemical properties, toxicity, and potential for resistance development.

Inert ingredients, while not directly involved in controlling mosquitoes, play essential roles in the formulation. These can include solvents, emulsifiers, and stabilizers. All inert ingredients must be disclosed to and comply with EPA guidelines for safety.

The formulation must be stable and compatible with the intended mode of application (e.g., spraying, fogging, granular application). Stability studies determine a product’s shelf life and prove that the product maintains its efficacy in that period.

Manufacturers must ensure that all ingredients used in the formulation comply with relevant regulatory standards. This may involve providing documentation of the purity and quality of each ingredient.

Compatibility testing is essential for products requiring specialized application equipment (such as sprayers or foggers) to verify the swath or area where a formulation can be effectively delivered by application equipment.

Manufacturers can begin the application process for EPA registration after collecting the necessary data and finalizing the formulation. This section outlines the steps involved:

Manufacturers must complete the required application forms, typically including Form 8570-1. This form gathers essential information about the product, formulation, and intended use.

Alongside the application form, manufacturers must compile and submit a comprehensive set of supporting documents. These may include the above-outlined efficacy data, safety studies, formulation details, and environmental impact assessments.

The EPA charges registration fees, which vary depending on factors like the type of product and the scope of the application. Manufacturers must pay all applicable fees in full to move forward with the registration process.

Once the application is submitted, it undergoes a thorough review process by the EPA. This section outlines the stages of the review process, which can take from 6 months up to two years:

The EPA conducts an initial assessment to ensure the application is complete and all required documentation has been provided. Any missing or incomplete information may result in a request for additional materials.

Staff at the EPA meticulously examine the scientific data provided in the application, assessing the quality, validity, and relevance of the studies conducted by both the product manufacturer, as well as other researchers, labs, and organizations on the actives contained within the product.

A critical aspect of the review process involves assessing potential risks associated with the product. This includes evaluating the impact on human health, non-target species, and the environment. The EPA concludes if the benefits of using the product outweigh any potential risks.

The EPA reviews the proposed product labeling to ensure it complies with regulatory standards with clear and accurate information about usage instructions, safety precautions, and any necessary warnings. This can include issuing decisions, limitations, labeling changes, packaging changes, marketing requirements, and more.

After receiving registration, manufacturers must fulfill certain responsibilities to maintain compliance with EPA regulations:

Manufacturers are required to keep detailed records of production, distribution, and sales of the registered product. They must also promptly report any adverse effects of the product’s use.

The EPA regularly inspects to confirm the product meets regulatory standards, conducting assessments of production facilities, labeling compliance, and adherence to reporting requirements.

Registered products are subject to periodic re-evaluation to ensure continued effectiveness and safety. Manufacturers must also renew their registrations to maintain compliance with EPA regulations.

Navigating the EPA registration process for mosquito control products is a complex but crucial step in ensuring the safety and efficacy of these essential tools for public health.

By conducting thorough data collection, formulating products with care, and adhering to EPA guidelines, manufacturers contribute to effective mosquito control strategies that protect public health and the environment.