How do Professional Mosquito Control Products Work?

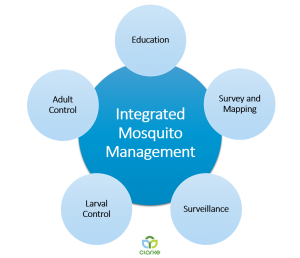

Communities all across the country rely on mosquito control products and services to improve the comfort and quality of life for residents. The EPA recommends an integrated mosquito management approach, which takes a holistic approach to mosquito control and involves all of the following management strategies:

Adult mosquito control treatments are often the most visible element of a community’s mosquito management program and often come with a lot of questions about how they work. This article breaks down the basics of adult mosquito control applications.

Adult mosquito control products are commonly referred to as “adulticides.” They are highly refined, EPA-registered insecticides designed specifically for mosquito control. Adulticide formulations contain an active ingredient and inert components that work together to control adult mosquitoes in-flight at the time of the application. They are most commonly applied through a ULV sprayer attached to a truck, ATV, or even a fixed-wing airplane.

Ultra-low volume (ULV) sprayers turn a liquid mosquito control product into an ultra-fine spray cloud or mist, made up of tiny droplets. A common reference point for ULV droplets is that 15 droplets could fit on the head of a pin! These droplets move through the air with the wind at the time of the application to make contact with flying adult mosquitoes.

Ultra-low volume (ULV) sprayers turn a liquid mosquito control product into an ultra-fine spray cloud or mist, made up of tiny droplets. A common reference point for ULV droplets is that 15 droplets could fit on the head of a pin! These droplets move through the air with the wind at the time of the application to make contact with flying adult mosquitoes.

In order to be effective, the droplets need to make physical contact with the flying mosquito, so ULV applications usually start at dusk or dawn when local mosquito populations are most active. They do not have any residual effect – they work only at the time of treatment to quickly reduce mosquito populations. Once applied, the product begins to break down rapidly and dissipates 5 to 30 minutes later, depending on the formulation and weather conditions.

There is a range of application rates used for mosquito control, as detailed on a product label. Typically, less than one ounce of formulated product per land acre will be used during a ULV application for mosquito control. For reference, a land acre is about equivalent to the size of a football field or three suburban lots.

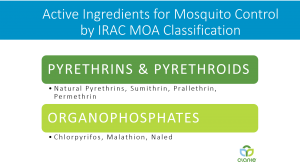

There are many, many different branded products and insecticide chemicals used for mosquito control. All available EPA-registered products fall into one of two chemistry categories – pyrethroids or organophosphates. These two chemistry classes use different “modes of action” to disrupt the mosquito’s nervous systems and ultimately kill adult mosquitoes.

The need to develop a new mode of action for adult mosquito control is great. It has been well over 30 years since a new class of chemistry or mode of action has been introduced for public health mosquito control use. To extend the useful life of all available mosquito control products, rotating products from both chemistry classes and routinely monitoring local mosquito populations for resistance is product stewardship best practice.

Most ultra-low volume mosquito spray applications are done at dawn or dusk when mosquitoes are most active. The more mosquitoes that are up and flying at the time of the treatment, the more relief a community can realize after a ULV treatment.

In an integrated mosquito management program, surveillance data on local mosquito population levels and the presence of arbovirus disease will play a large role in scheduling mosquito control treatments. Resident complaints about nuisance levels will also play a role in deciding when and how often to treat for mosquitoes, along with weather conditions, local events, budget, and other timing considerations.

When EPA-registered products for controlling mosquitoes are applied according to their label instructions, the EPA has determined that “mosquito control treatments do not pose unreasonable risk to public health and the environment.”

Prior to registering a product, the EPA evaluates products thoroughly to be sure there is a “reasonable certainty of no harm” to humans, animals, and the environment from their use. Any EPA-registered product for mosquito control has passed rigorous tests required by the EPA and has been approved for use in various treatment sites, all listed on the specific product label.

Barrier applications for mosquito control treat foliage and other surfaces where adult mosquitoes rest during the daytime hours. A barrier product is typically applied with a backpack sprayer, and it is formulated to have lasting power after applied. Depending on the product used and weather conditions, barrier applications will control adult mosquitoes who land on a treated surface for 7 to 21 days.

Barrier applications for mosquito control treat foliage and other surfaces where adult mosquitoes rest during the daytime hours. A barrier product is typically applied with a backpack sprayer, and it is formulated to have lasting power after applied. Depending on the product used and weather conditions, barrier applications will control adult mosquitoes who land on a treated surface for 7 to 21 days.